|

|

| |

| |

|

|

NOTA

INDUSTRIES

Nota

Market,

Opp.

Punjab &

Sind

Bank,

Focal

Point,

Sherpur

Road,

Ludhiana-141010.

Punjab

INDIA.

Email:

info@notatex.com |

|

|

| |

| |

|

Tele:+91-161-2674700

+91-161-2672750

Fax:

+91-161-2672750 |

|

|

|

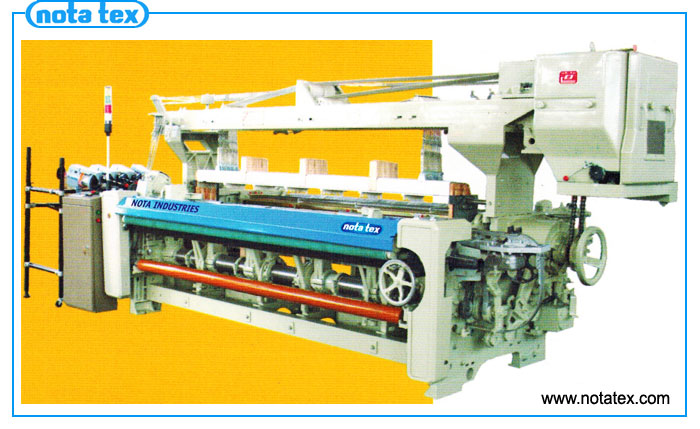

>> RAPIER

LOOM MACHINE - MODEL

NT 738 RAPIER LOOM |

|

|

|

NT738 rapier loom series are

well designed with precision

manufacturing facilities and

advanced detective instruments,

suitable for weaving cotton,

wool, hemp and synthetic fibres

into high-grade fabrics.

Based on the design of NT736

rapier loom series, it enjoys

the features of strong and

durable structure, smooth

performance, high ratio of

performance/price and wide

weaving range. It is very

popular among our users.

Transmission: The high

speed crank is enabled by the

clutch. It provides fast startup

and is ideal for high speed

working.

Beating Motion: The

beating is carried out by

specially designed crank and

levers with double-side drives,

it increases the beating area,

and can ensure the beating

strength of high-density and

heavy fabrics.

Wefting Insertion: It

adopts 6 levers to carry out the

wefting insertion, which

provides a better motion of the

grippers and the weft yarn keeps

a stable tension for proper

gripper connection during high

speed working of the loom.

Let-off Motion: The main

parts of the let-off motion such

as the worm wheel and the worms

are closed in an oil bath, which

provides accurate matching of

gears and extends its life.

Take-up Motion: the

continuous take-up motion

provides smooth fabric surface.

Control: It is controlled

by micro-computer, with

automatic stop upon warp and

weft broken. LCD shows the

weaving parameters and

statistics data, weaving

parameters are adjustable from

the panel. |

|

|

|

|

RAPIER LOOM MACHINE |

|

|

|

TECHNICAL SPECIFICATIONS |

| Reed

Space (cm) |

200 |

230 |

280 |

300 |

340 |

360 |

| Speed

(rpm) |

270-280 |

250-260 |

200-210 |

180-190 |

160-170 |

150-160 |

|

|

|

| Motor

Power |

2.2kw 440v 3-phase 50Hz |

| Shedding

Device |

Upper mechanical dobby

machine with under motion |

| Wefting

Motion |

6-levers wefting motion,

center connection |

| Beating

Motion |

4-levers and short levers |

| Let-Off

Motion |

Active let-offmechanism in

oil bath, beam disk diameter:

680mm |

| Take-Up

and Fabric Roller |

Continuous take-up, max

fabric rolling diameter: 420mm |

| Warp Stop

Motion |

Automatic stop with 6 row

warp dropper stand |

| Weft Stop

Motion |

Automatic stop with piezo-ceramic

weft yarn detector |

| Color

Selection |

Dobby or electronic control,

6 colors |

| Selvage

Device |

Leno device |

| Loom

Operation |

By control button on both

side of loom |

| Electric

Control |

Controlled by LCD-display

control panel, loom stop and

start functioned by the

electro-magnet clutch. |

|

|

|

|

|

|

|

|

|

|

|

|